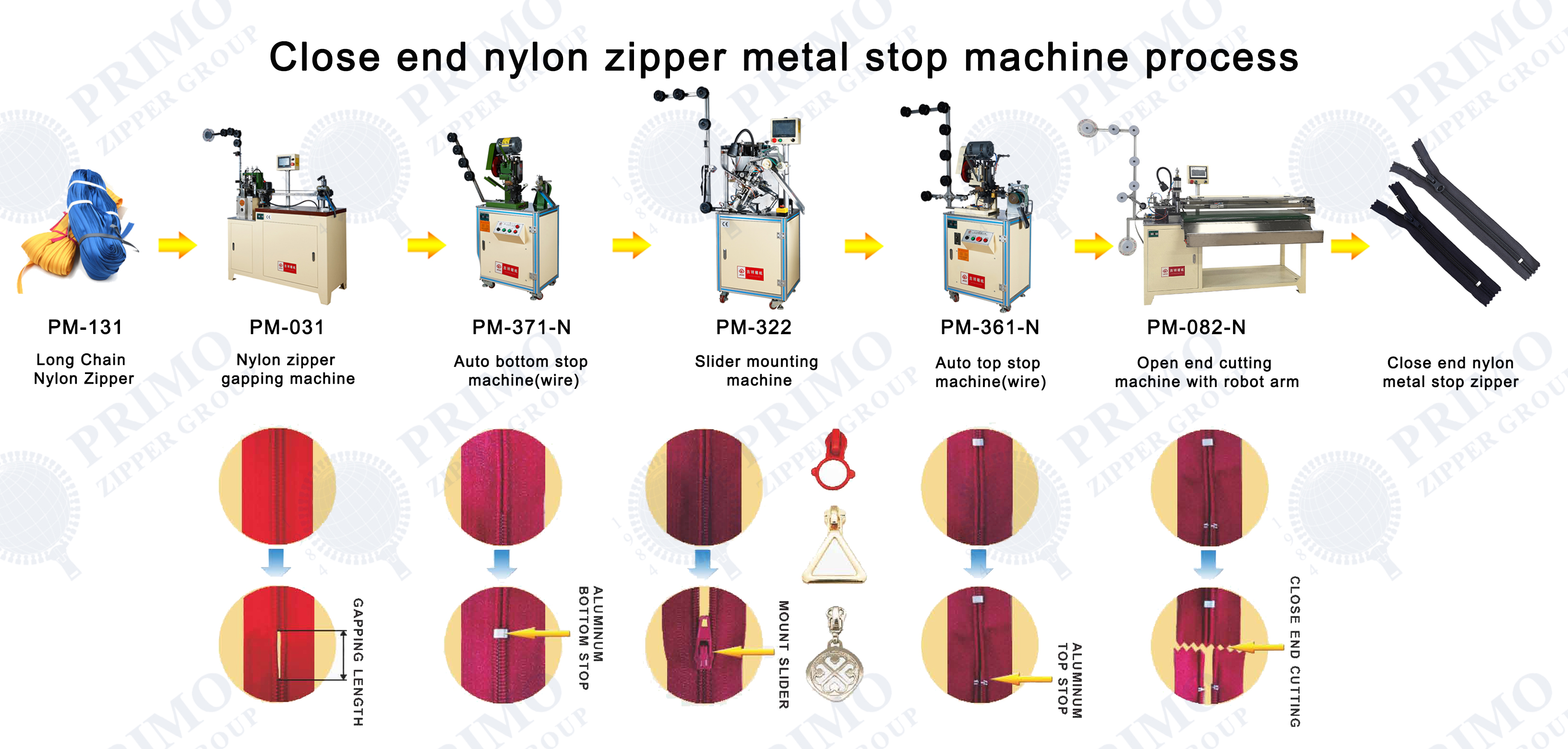

Main Feature

This machine adopts robot arm to pull the zipper when it cut, it apply to all shape type slider to passthe cutting knife, hook location, the cutting edge is smooth, operate easily,improve effciency

|

CUTTING MACHINE

|

|

|

Model

|

PM-092

|

|

Power

|

0.75KW

|

|

Production

|

1600pcs/H with 60cm zipper

|

|

Volt

|

220V

|

|

Machine Weight

|

250Kgs

|

|

Machine Dimensioms(L×W×H)

|

2.15×0.85×1.90 m

|

|

Shipping Measurement(L×W×H)

|

1.00×0.70 ×1.70 m

|

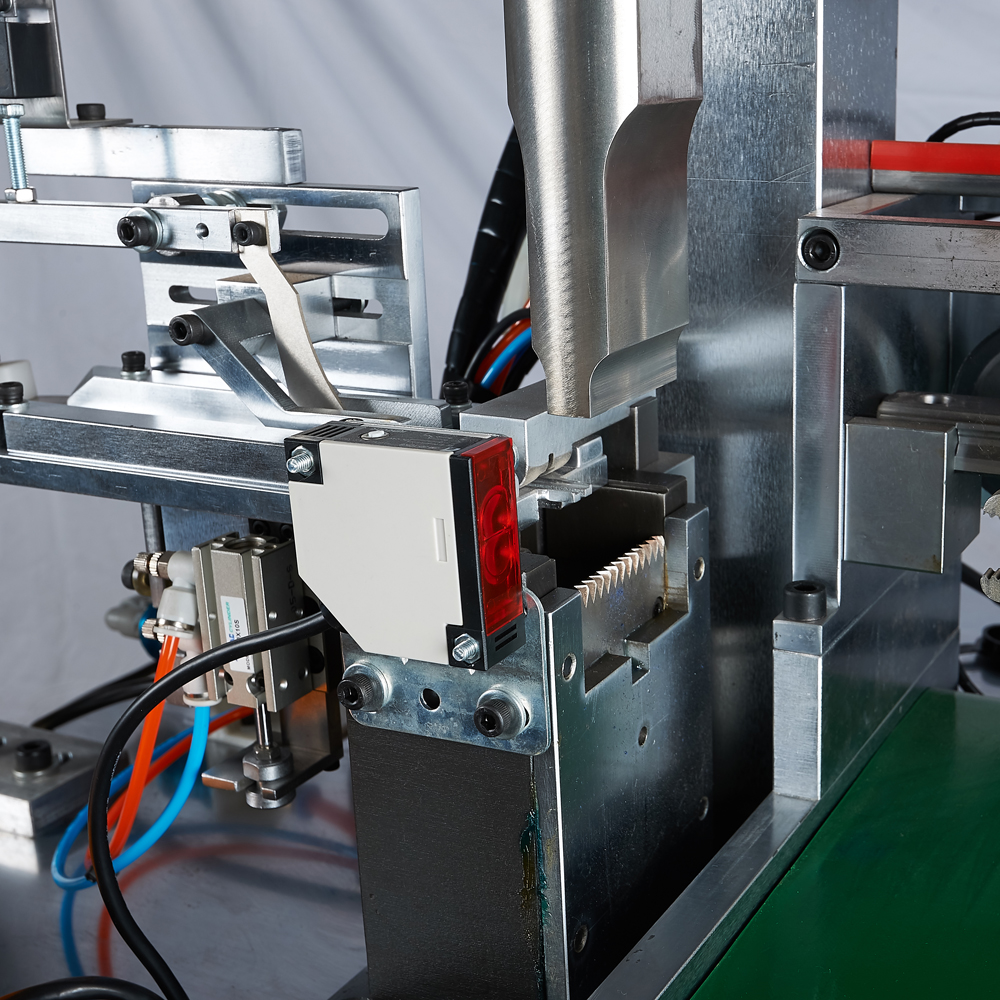

Ultrasonic Cutting Die System

This advanced cutting system utilizes high-frequency ultrasonic energy to create perfectly sealed zipper ends with superior edge integrity.

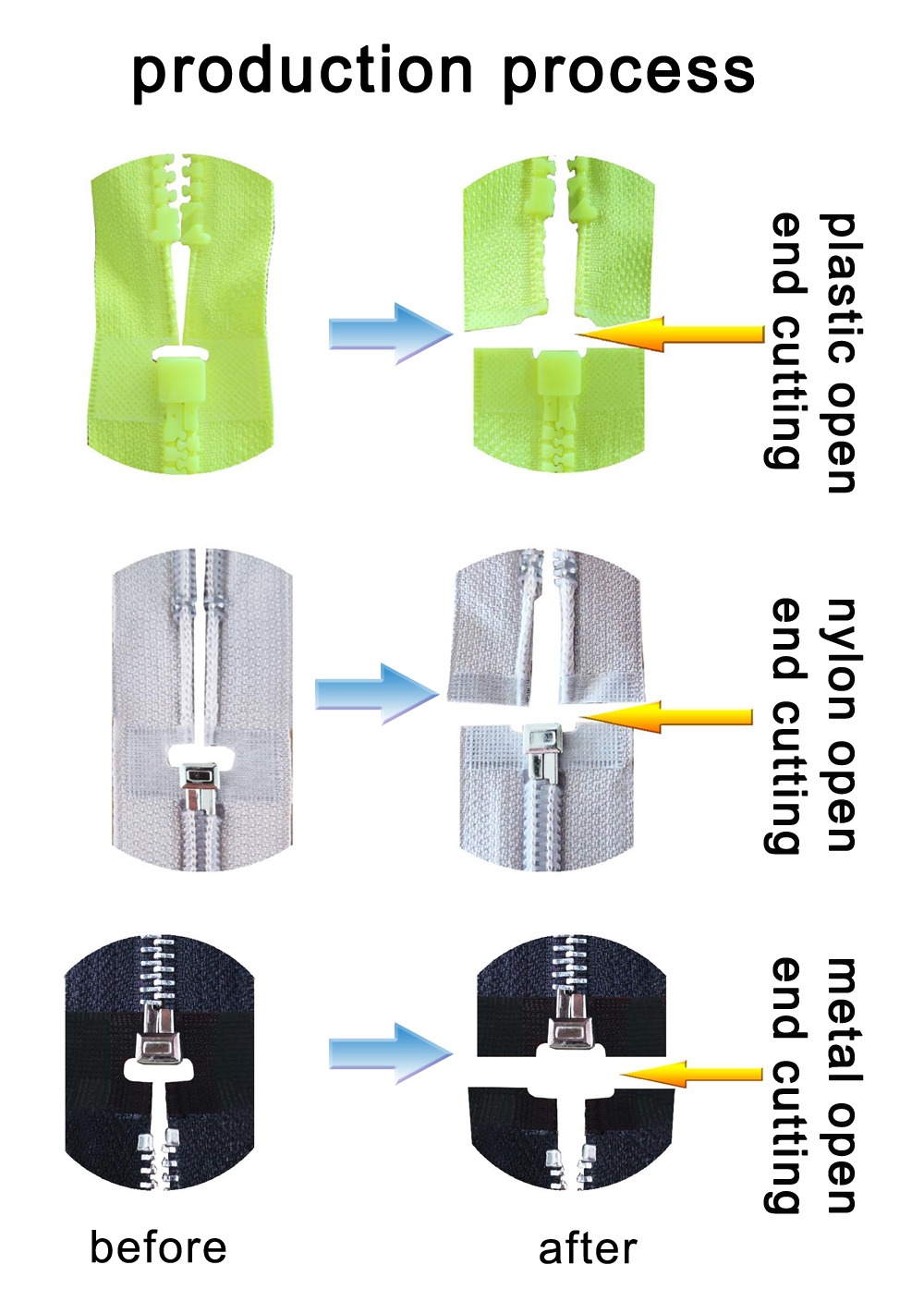

Cutting Process

Energy Conversion -20kHz transducer generates vibrations

Focused Cutting - Titanium horn amplifies and directs energy

Molecular Bonding - Heat-free localized fusion

Clean Release -Self-cleaning die design

This pre-cutting alignment system ensures zipper tapes maintain perfect positioning beforeentering the cutting mold.

Positioning Process:

Entry Guide Rollers - Initial tape alignment

Precision channels - Constrained path guidance

Final Orientation -Mold-ready positioning

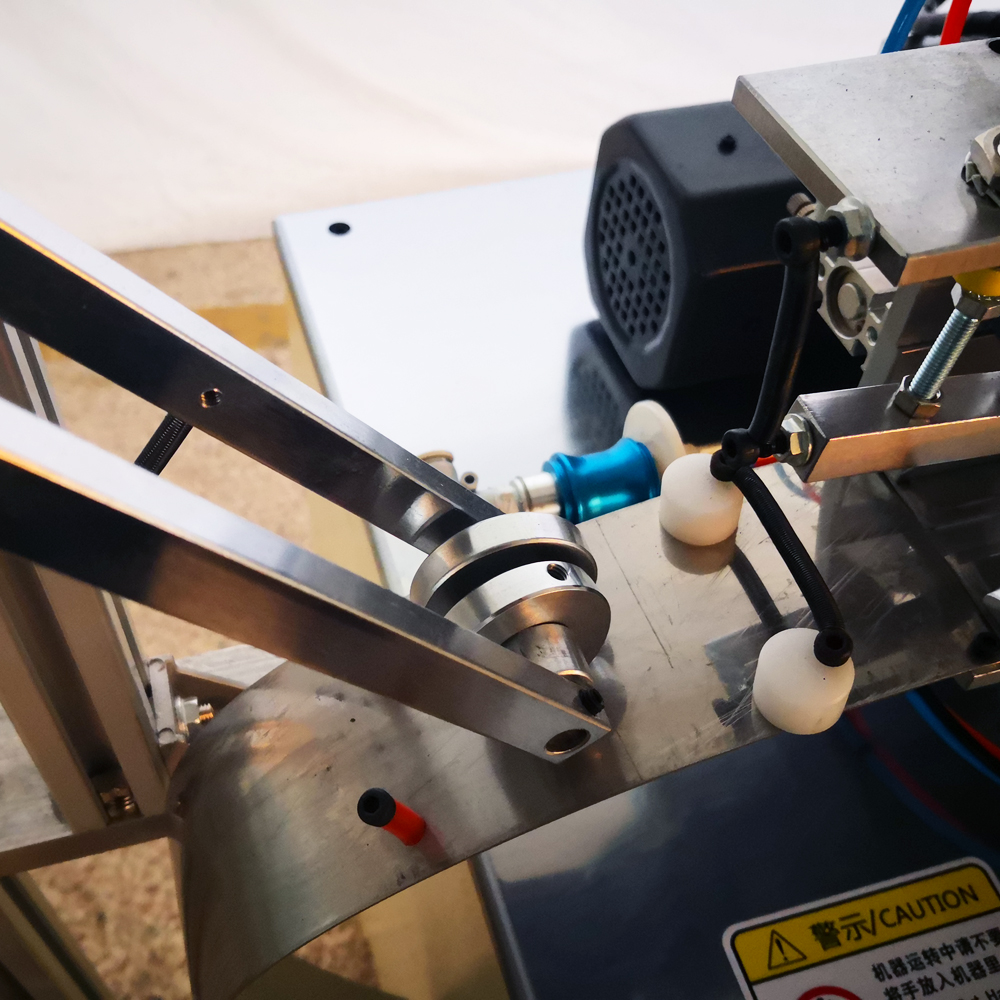

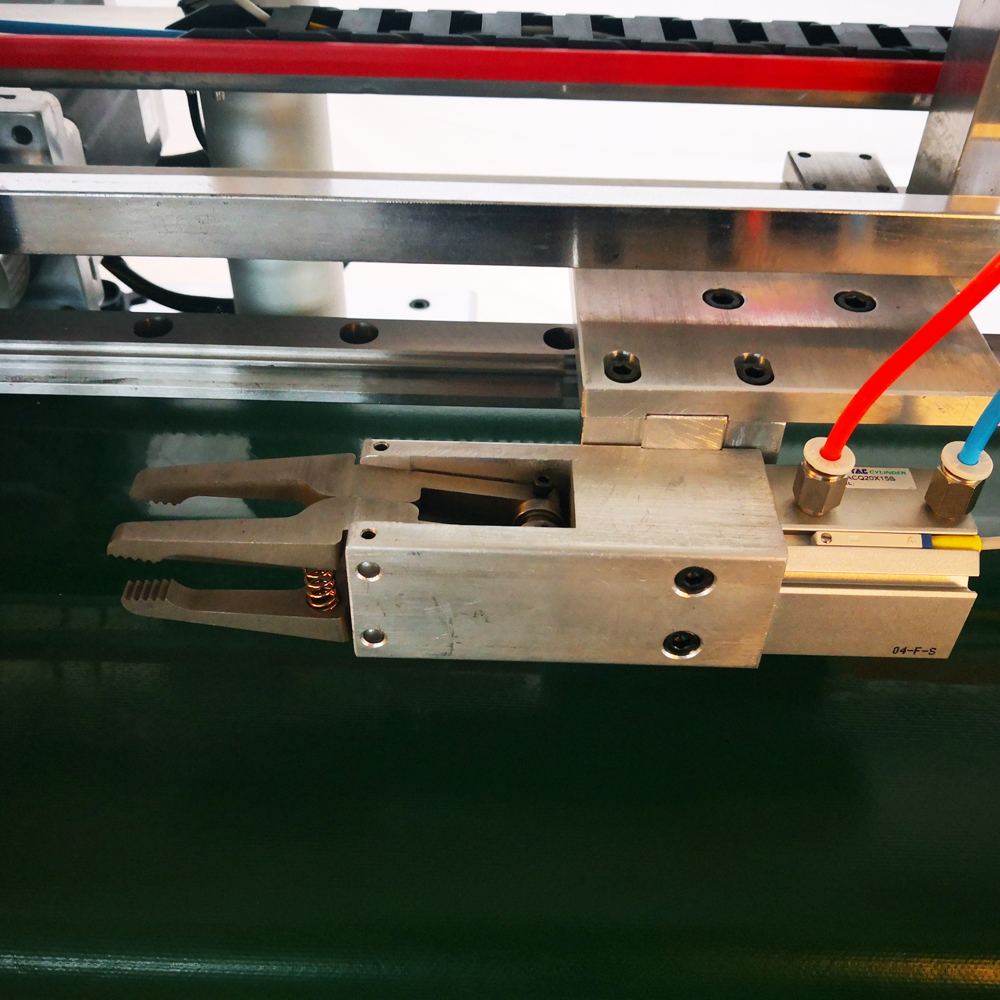

Robot Arm System for Zipper Handling

This versatile robotic system automatically extracts all zipper types from cutting dies, featuringuniversal compatibility with any slider shape.

Operation sequence

Adaptive Gripping -Shape-agnostic end effector engages slider

Precision Extraction -Controlled removal from die cavity

Oriented Placement - Consistent positioning for downstream processes

Efficiency

High-speed operation boosts productivity with minimal downtime.

Precision

Servo-controlled accuracy ensures perfect zipper placement every time.

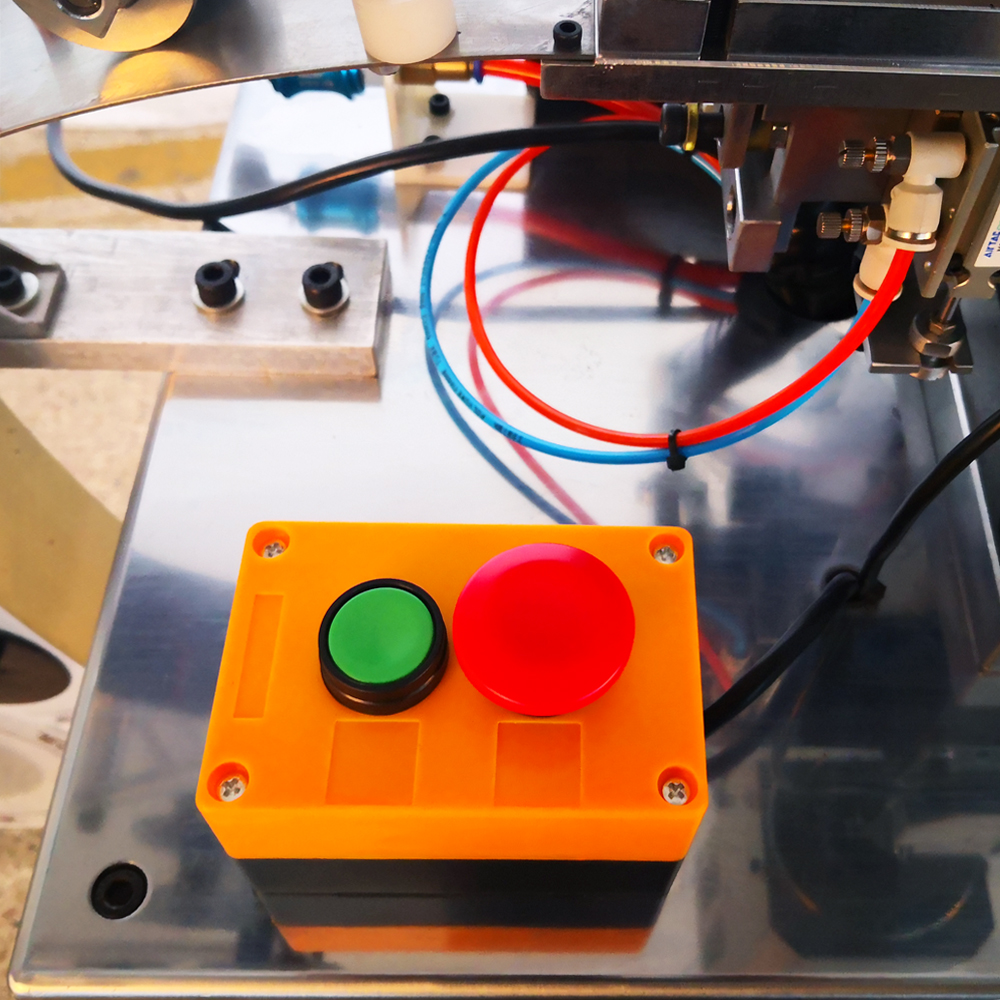

User-Friendly

Intuitive controls and quick setup for effortless operation.

Durability

Industrial-grade construction for long-lasting performance.

Wenzhou Primo Zipper Machine Co., Ltd(JESO) is a professional zipper making machine.

factory has been engaged in 1984. have 40 years of experience in zipper making machine,provides a combined service in the zipper production line.

If you have any enquiny about quotation or cooperation,please feel free to emal us at [email protected] or use the folowing enuiry form.

Our sales representative will contact you within 24 hours. Thank you for your interest in our products